Dipl.-Ing. Klaus Specken, Managing Director

Together with our 250 employees, we serve you from our headquarters in Meppen, Germany.

We consider ourselves a system partner who advises and listens to you with our no-nonsense approach; we ask specific questions so that together with you we can develop the best possible gearbox solution for your application. We can also manufacture it in a cost-efficient manner in small quantities.

No matter how complex your challenge is: We're ready to take it on.

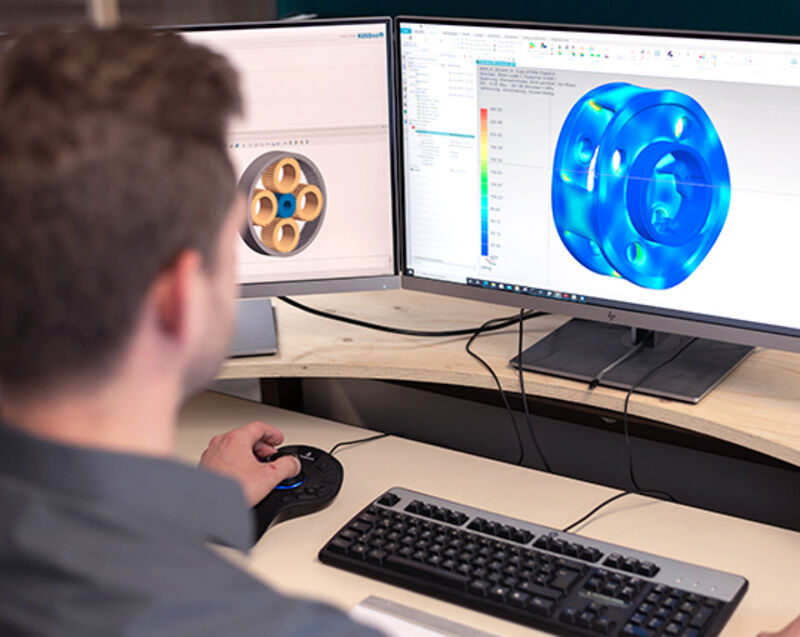

Every year, we manufacture around 800 different gearbox types, most of which are application-specific special solutions. With more than 20 engineers in our in-house development department, we integrate ourselves into the development processes of our customers early on in order to develop the optimal gearbox solution for their individual requirements in close cooperation.

From milling and drilling of cast iron and steel raw parts to turning, gear cutting and heat treatment including finishing, to assembly, test runs and painting, we manufacture almost all gear components in-house. The result: flawless quality made in Germany, short delivery times, outstanding cost-efficiency.

At Rögelberg, we are committed to building long-term, trusting relationships with our business partners. We win over our customers with our expertise, transparency and reliability. And with the best solution – technically and economically.

A passion for developing and manufacturing the best gearbox solution in addition to a high level of quality awareness are at the core of our daily activities. In-depth quality controls and quality management in accordance with DIN ISO 9001:2015 ensure that each of our gearboxes meets our expectations and those of our customers.