The drive is at the heart of a vehicle. High rotation speeds, noise minimisation and high efficiency – these are the challenges of electrifying a drive train. Whether for the construction site, train track or road. Whether electric wheel loaders, monorails or fully electric trucks. With electrified drive trains, we do our part to create more efficient, environmentally friendly mobility.

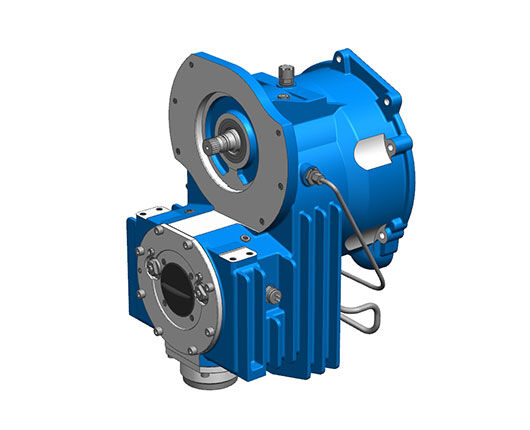

| Shiftable bevel-spur gearbox for driving an extinguishing water pump, a generator or a hydraulic auxiliary line depending on the shifting position – e.g. for a range extension system of a hybrid fire brigade fire engine. |

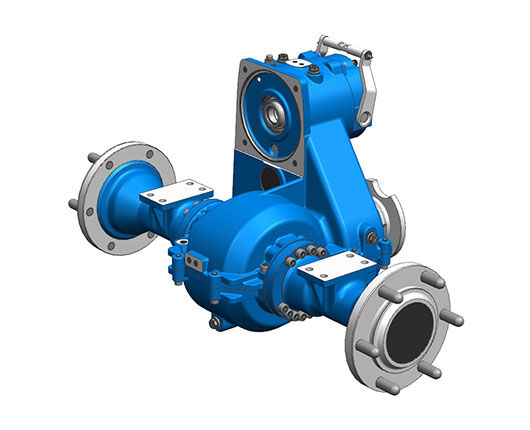

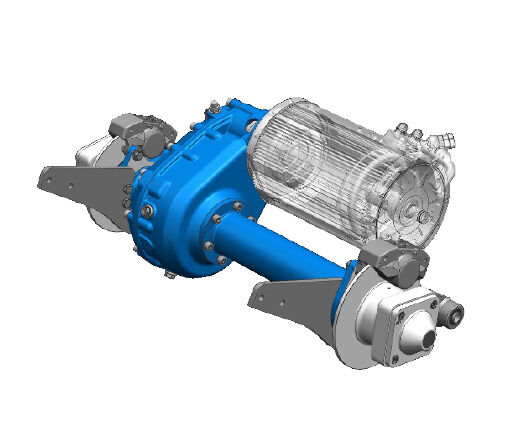

3-stage spur gear differential gearbox with electric motor mounted offset, parallel to the axle – e.g. for electric forklifts.

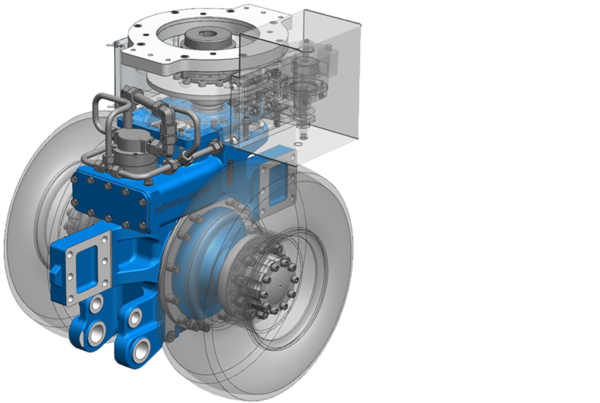

Multistage axle drive with a high ratio and bevel gear differential – e.g. for an electric yard loader.

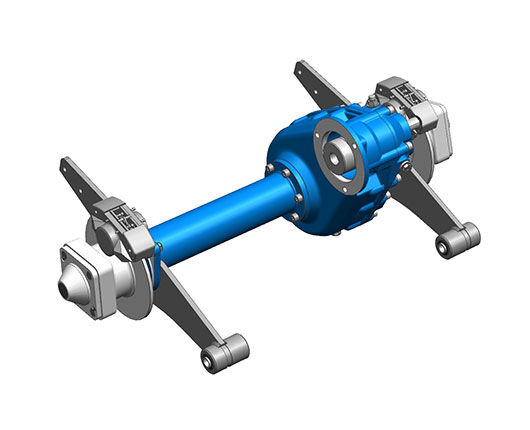

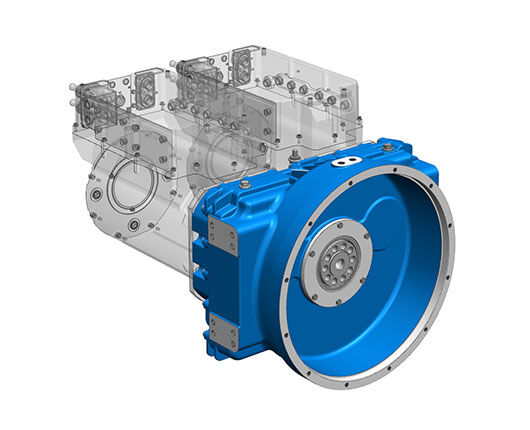

Double spur gearboxes for driving a fully-electric truck. The gearbox cumulates the power of two electric engines on an output shaft and embodies the connection geometry of a comparable diesel engine at the output. As a result, e.g. the standard truck speed-change gearbox can still be used.

3-stage spur gear differential gearbox with electric motor mounted offset, parallel to the axle – e.g. for electric forklifts.