Rögelberg's success story dates back to the beginning of agricultural mechanisation. We have and continue to contribute to decisively shaping the further development of agricultural machinery technology. Today, drive solutions from Rögelberg are used in a multitude of soil processing, harvest and transport machinery: from tillers to power harrows, from hydraulic manure spreaders to loader wagons, from corn choppers to self-propelled sugar beet harvesters.

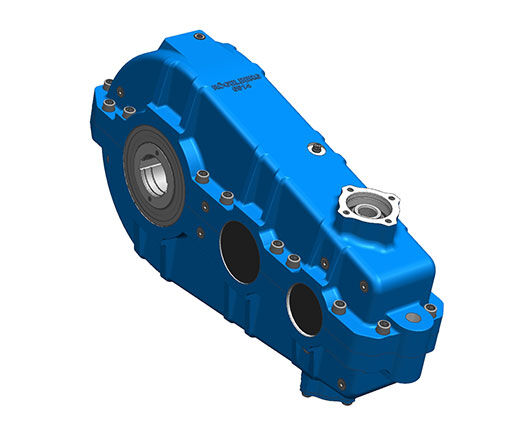

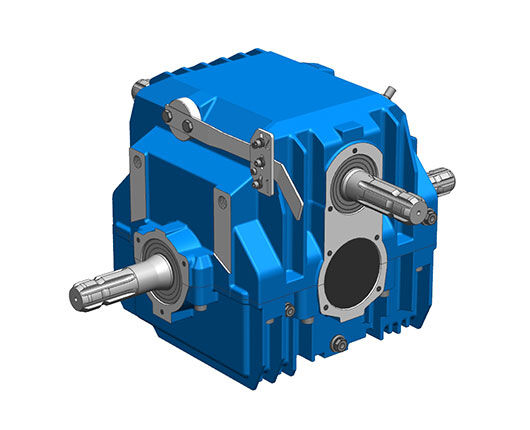

Spur gearbox for power distribution in a corn chopper. The primary power is mechanically fed directly to the chopper drive. The power is also branched to different hydraulic lines.

Double bevel gearbox for propelling both V-shaped arranged disc coulters using a hydraulic motor – e.g. in a self-propelled sugar beet harvester.

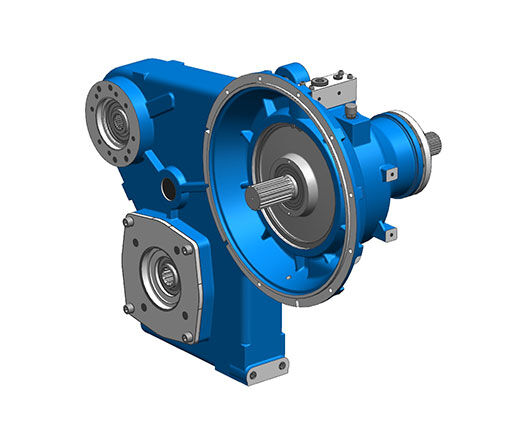

Multi-stage bevel-spur gearbox for the hydraulic scraper floor drive with a connection option for mounting two hydraulic motors in order to form a hydraulic shifting system – e.g. in a large universal spreader or a silage transport wagon.

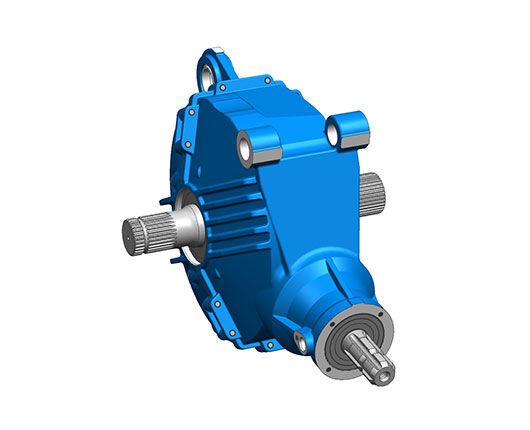

Speed-change gearbox for achieving two different gyroscopic speeds and for central power distribution to the left and right drive train – e.g. with a folding power harrow.

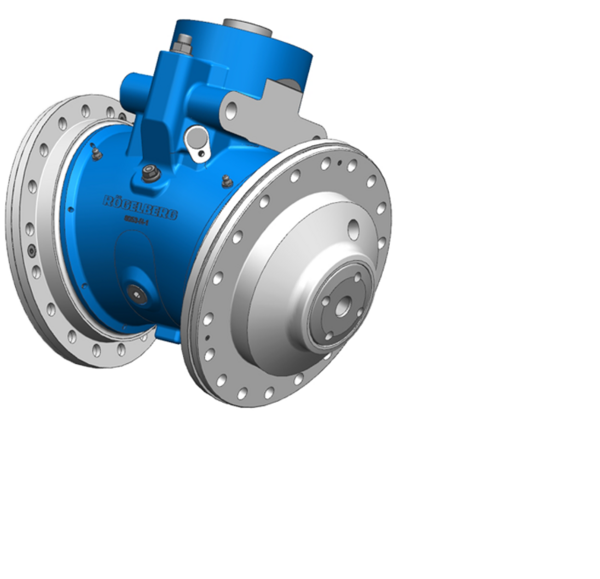

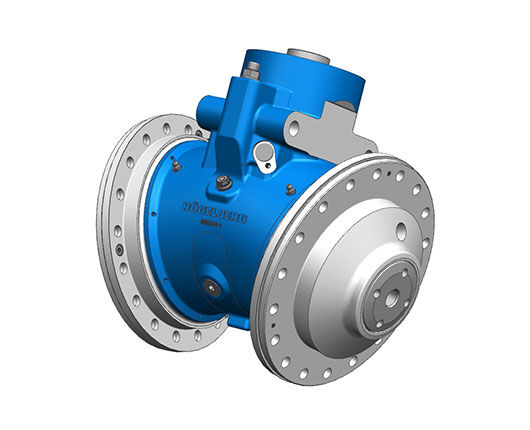

Bevel gearbox with bolt mounting for optional determination of a support force, which is a reference value for the torque – e.g. for a loader wagon.

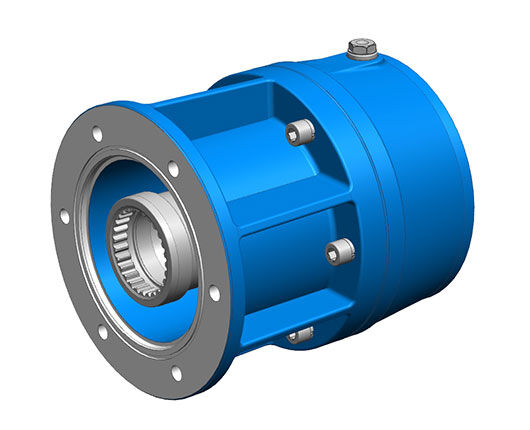

Planetary gearbox between an electric motor and a stirrer blade – e.g. for propelling a submersible agitator in a biogas plant.

Gear set consisting of different individually adjustable standard bevel gears – e.g. for driving the vertical spreader unit.

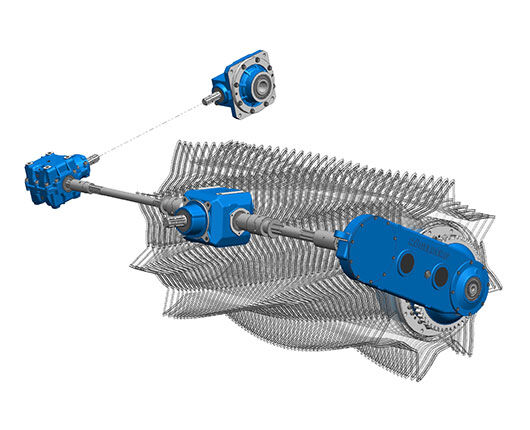

Bevel gear set, among other things, with our central spreading device gearbox and multiple horizontal roller gearboxes – for example, for a large universal manure spreader.

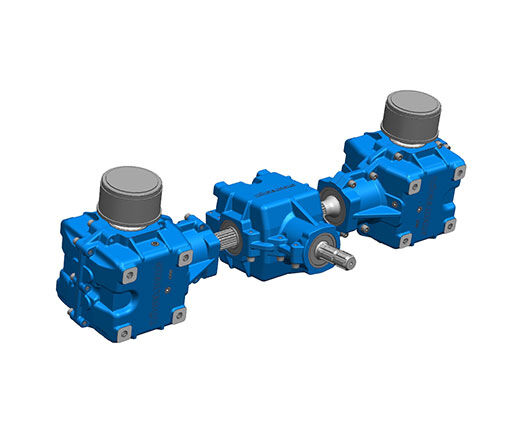

Gear set, among other things, with our individually adjustable standard bevel gearboxes – e.g. for driving the cutting rotor unit and a horizontal roller in a loader wagon.